- Introduction

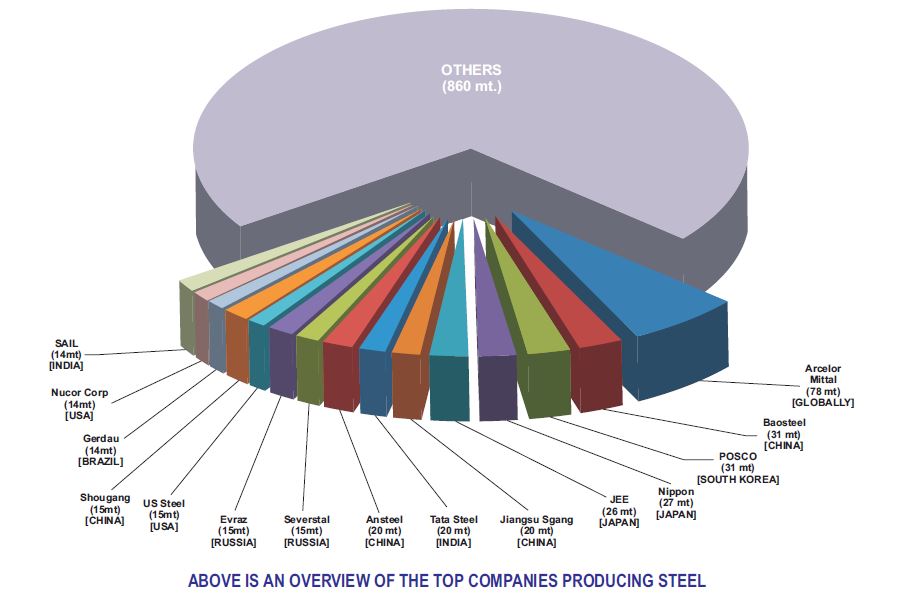

- Industry Overview

- Steel Making Process

- Product Line

- Seal Material

- Application Overview

Sealing Solutions in the field of Steel Industry

Max Spare Limited (formerly Spareage) is a leading seal manufacturer in India providing standard & customised sealing solutions to clients across industries. Having more than five decades of experience and expertise in serving the industrial clients, Marina Engineering Corporation with its wide range of seal profiles and elastomers is fully capable of serving Iron & Steel Industries.

Marina Engineering Corporation is involved in all different stages of Iron & Steel making process.

High Speed

High Pressure

High Temperature

Operating Reliability

Economy & Long Life

Customised Solutions

Marina Engineering Corporation thus understand these needs which comes across during selecting appropriate seals & elastomers.

Thus offers Standard and Customised seals for Rotating & Reciprocating applications.

Marina Engineering Corporation offers high pressure hydraulic seals upto 700 bar and rotary seal for high speed upto 30mtr/sec in rolling mill applications.

It is not only the seals design an issue, but the easy installation under challenging environment, Marina Engineering Corporation offers split seal solutions which reduces down time.

With the team of competence engineers, we are capable to offer sealing solutions without carrying out major modification in the existing setup. Our team is involved from start to the designing, installation and monitoring the performance of the sealing solutions.

A global presence enabels Marina Engineering Corporation to deliver sealing technology to places where it matters the most. From Asia to North America and Europe, we are just a phone call away from delivering the best sealing solutions.

Marina Engineering Corporation involvement in Iron & Steel making process

Material Handling Plant

Blast Furnance

Coke Oven

Continuous Casting

Hot & Cold Rolling Mill

Steel Products

Hot rolled sheets

Cold rolled sheets

Flat products

Galvanized sheets

Long Products

Long rail products

Rolled wires

Seamless pipes

Marina Engineering Corporation are present at all different stages in steel industry across the globe. Start from iron ore processing till finished coils. Marina Engineering Corporation has been providing technically advanced seals solutions to meet the needs of applications in these industry. Marina Engineering Corporation involvement starts from application study, designing, material compounding, manufacturing to installation and monitoring performance.

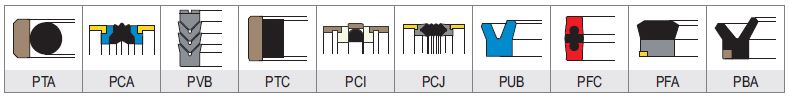

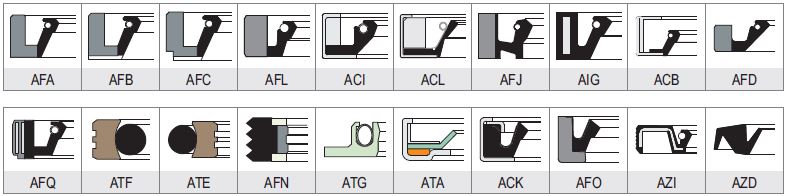

Piston Seal

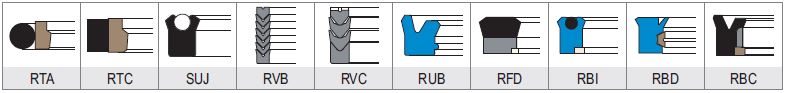

Rod Seals

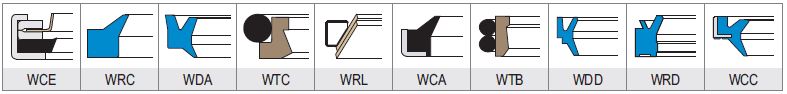

Wiper Seals

Rotary Shaft Seals

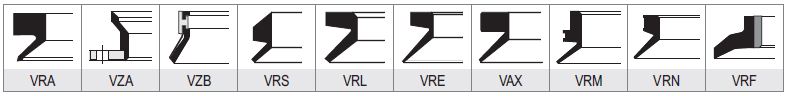

V-Rings

Pneumatic Seals

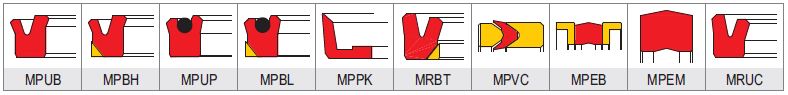

Jet Express Seals

Acrylonitrile Butadiene Rubber (NBR)

| Hardness | Spareage Code |

|---|---|

| NBR 70°/75° Shore 'A' | NT4/b |

| NBR 80°/85° Shore 'A' | NT5/b |

| NBR 90°/95° Shore 'A' | NT6/b |

Nitrile rubber is the sealing material most frequently used in Hydraulic & Pneumatic systems because of its excellent resistance to mineral oil based fluids, greases, water & hydrocarbon fuels. It has good physical characteristics such as abrasion resistance and good compression set.

NBR is not suitable to Aromatic hydrocarbons, chlorinated hydrocarbons, automotive brakes fluids, and some fire resistant hydraulic fluids.

Hydrogenated Acrylonitrile Butadiene Rubber (HNBR)

| Hardness | Spareage Code |

|---|---|

| HNBR 70°/75° Shore 'A' | NT42/a |

| HNBR 80°/85° Shore 'A' | NT42/b |

| HNBR 90°/95° Shore 'A' | NT34 |

HNBR with PTFE Filler

| Hardness | Spareage Code |

|---|---|

| HNBR 80°/85° Shore 'A' | NT34/b |

Polyurethane (PUX)

| Hardness | Spareage Code |

|---|---|

| 92° | PUX |

Polyamide (Nylon)

| Hardness | Spareage Code |

|---|---|

| M 95° | NY-X |

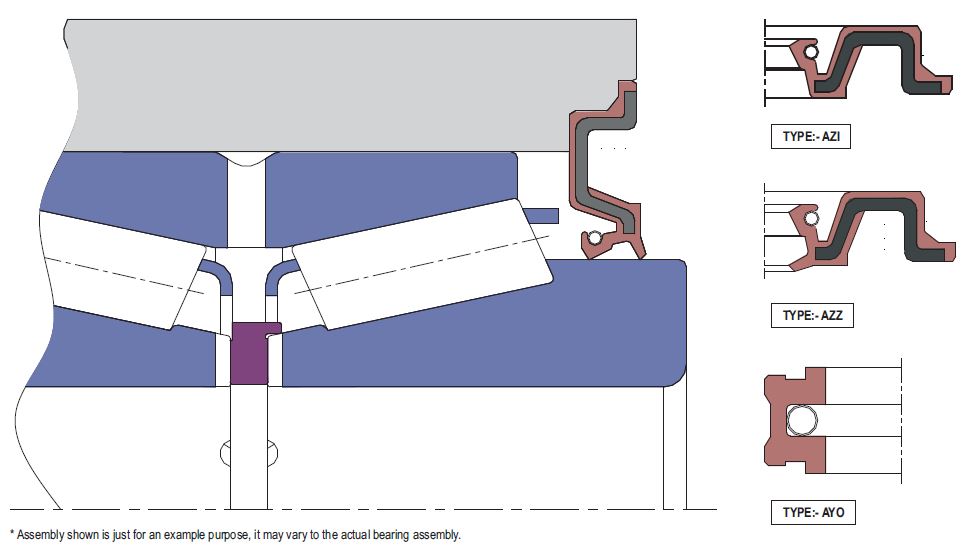

Taper Roller Bearing Seals -

Marina Engineering Corporation (Spareage) had developed inner & outer seals for Taper Roller Bearings used in work roll and intermediate roll chocks. AZI & AZZ seals are constructed with a metal insert with rubber covered outer diameter. Spring loaded single and dual lip made out of FKM or HNBR elastomer.

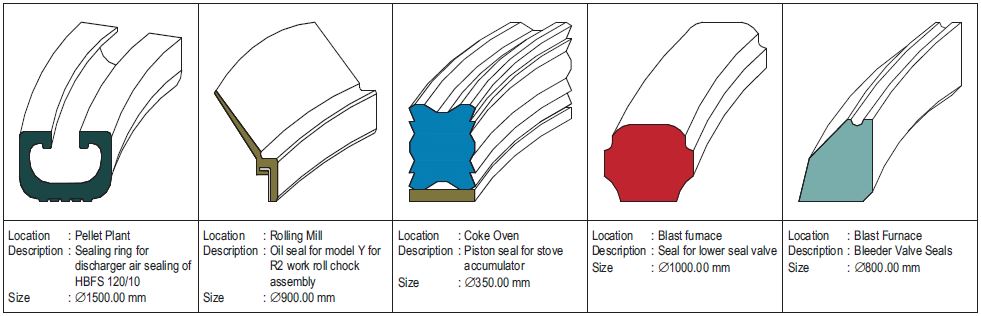

Special seals for different application in steel making process -

Marina Engineering Corporation is involved in supplying specially developed seals in various applications in different stages of steel making process. Seals for valves, actuators, accumulators, rolling mills, furnace equipments are supplied in different elastomer materials. The size range of these seals are covered upto 2 mtr. in diameter. You can place your trust on Marina Engineering Corporation for these kinds of special requirements.