- Introduction

- Product Line

- Pumps

- Motors & Gearbox

- Research & Development

Seals & Sealing elements for Pump, Motor & Gear Boxes in various industries

Max Spare Limited (formerly Spareage), is India’s leading seal manufacturer providing standard & customized sealing solutions to clients across industries. Having more than five decades of experience and expertise in serving the industrial clients, Marina Engineering Corporation established its products range in OEM & Replacement market.

Thus serving in various industries, our seals are widely use in pumps, motors & gearboxes. Marina Engineering Corporation is involved with many OEM manufacturer of this segment for process industries.

While selecting seals and elastomers many factors to be accounted such as,

High Speed

High Pressure

Temperature resistance

Media resistance

Operating reliability

Economy and long life

Customised solutions

Marina Engineering Corporation thus understand these needs which comes across during selecting appropriate seals & elasotmers for OEM and also in field at end users. Marina Engineering Corporation, full fledge R & D team is involved developing seals starts from rubber compound, design & upto endurance testing, which is conducted in-house.

Hence you can place your trust on Marina Engineering Corporation for any kind of seals required for pump, motor & gearbox. Our team is ready to cater your needs on time.

Pumps are used for a wide range applications to move fluids such as liquids, gases, slurries etc. These are different types of pumps such as water pump, hydraulic pump, vaccum pump and many other pump for high pressure, quiet operation, long life and many more features whenever the customer encounters with their critical operating conditions. Marina Engineering Corporation with its experience and expertise in sealing technology are able to offer appropriate recommendations and sealing solutions.

Marina Engineering Corporation also provides customised dimensions and designs in various materials such as NBR, Viton, Silicon, EPDM, HNBR, PTFE etc. for different temperature, applications media, pressure, speed, etc.

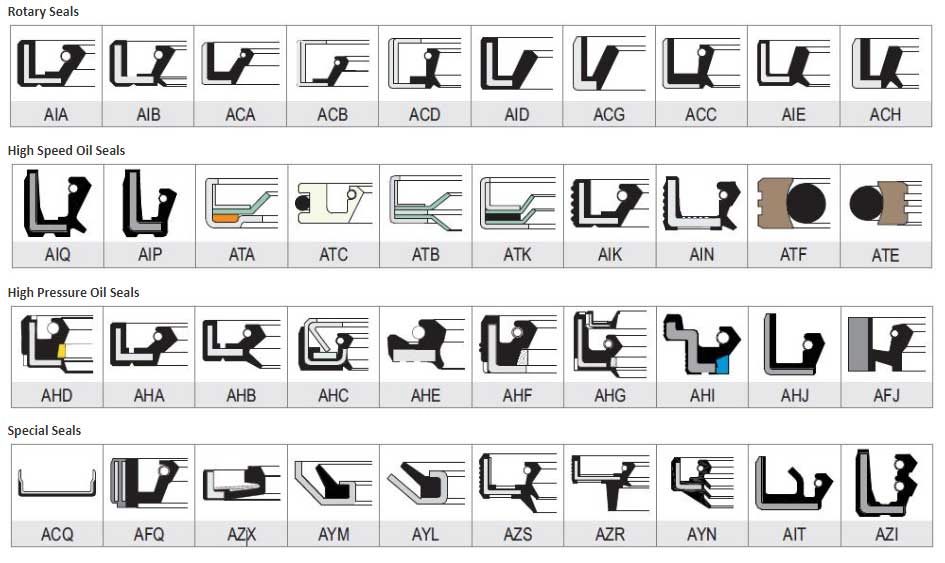

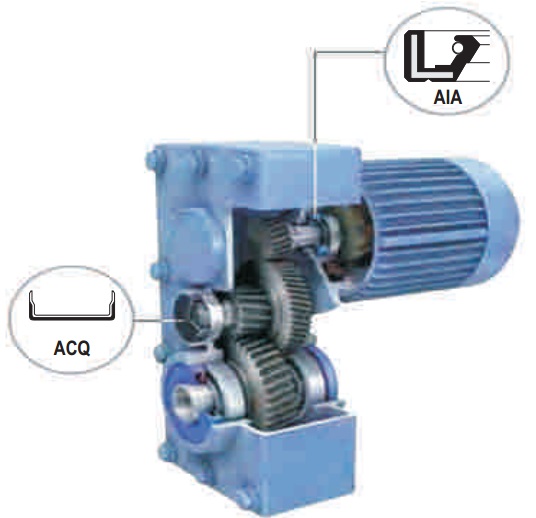

Marina Engineering Corporation sealing solutions for industrial gearboxes includes rotary seal, end caps and other sealing rubber elements. A general gearbox application are with two rotary seals i.e. input seal and output seal usually input seals are subjected to high speeds. Single lip and dual lip are common designs used for this application.

Other applications like high speed, high pressure, low speed, dry run, abrassive conditions are catered by offering special elastomeric compounds and PTFE material. Marina Engineering Corporation had developed special elastomeric compound with PTFE fillers which offers optimum service life in dry running conditions and having high wearing resistance. Marina Engineering Corporation have more than decades of experience working with OEM customers in this segment. We provide seals for various gearboxes used in many areas like power, transmission, transportation, construction, material handling, process industries and many more.

Marina Engineering Corporation offers many customised sealing solutions which are developed in-house with help of its State-of-Art Laboratory and advanced technologies to meet the international standards. Marina Engineering Corporation had a dedicated R & D team that offers support to technical consultation which helps to give the assurance to the customers about the offered sealing solutions. Marina Engineering Corporation conducts in-house testing on the rotary seals to confirm theorotical analysis for operating conditions, decrease the failure rates during trial runs and improve the efficiency on new seal developments. The conclusion of these testings strongly support us to recommend the seal design and material for the required end use application.