- Introduction

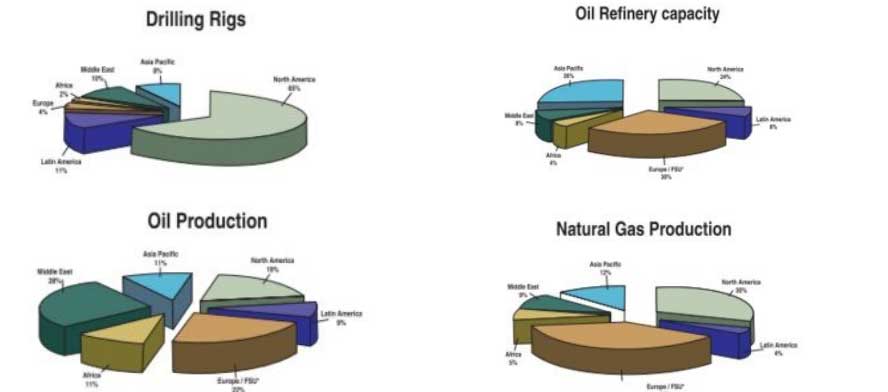

- Industry Overview

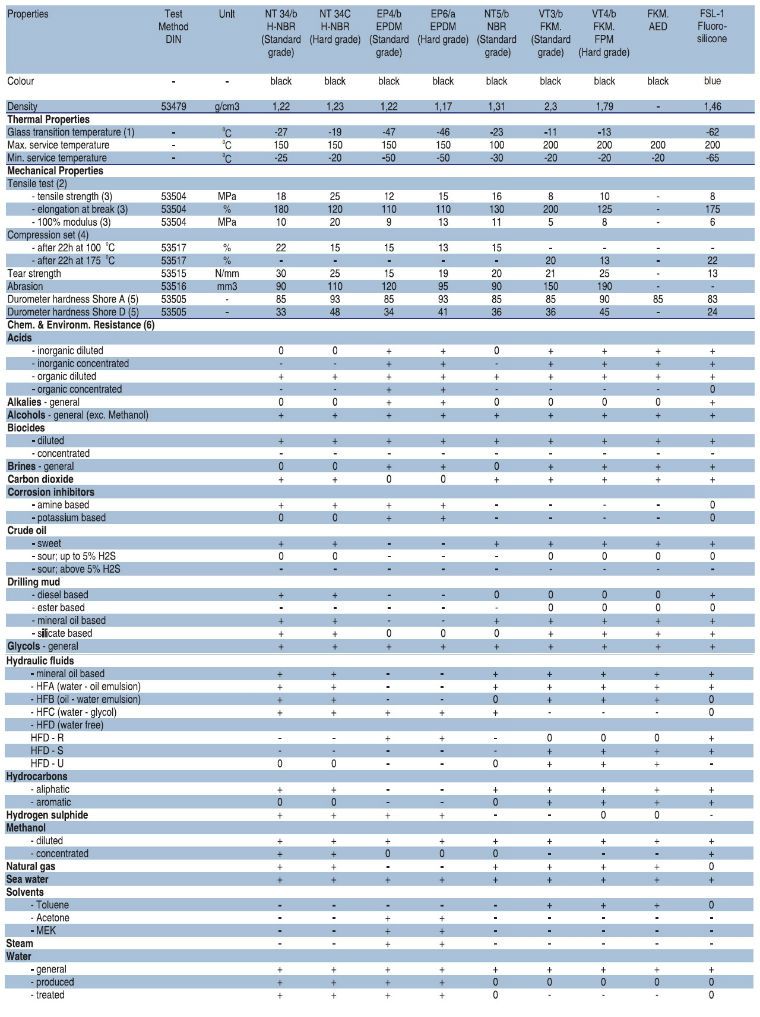

- Compliant Materials

- Rubber Elastomers

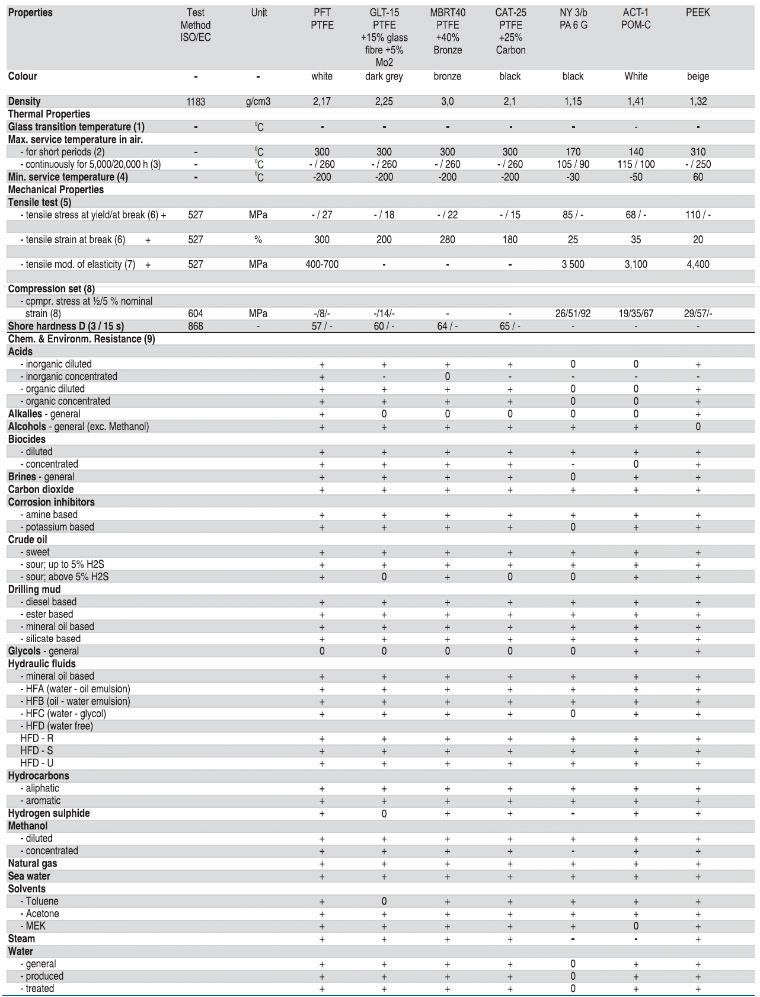

- Thermoplastics

Sealing Technology in the field of Oil and Gas Industry

Marina Engineering Corporation is India's No.1 seal manufacturer providing customized sealing solutions to clients across industries. Having more than five decades experience and expertise in serving the Industrial clients, Marina Engineering Corporation with its wide range of seal profile and elastomers is fully capable of serving the Oil & Gas Industry.

A global presence enables Marina Engineering Corporation to deliver our sealing technology to places where it matters the most. From Asia to North America and Europe, we are just a phone call away from delivering the best quality sealing solutions.

As one of the pioneers in the industrial seal segment, we have perfected the art of producing high quality seals, taking it to grater heights. so, whether you are an OEM or into repairing oilfield equipment, you can place your trust in Marina Engineering Corporation to provide top quality seals and components quickly at an economical cost.

No other industry poses a greater challenge to sealing technology the way the oil and gas industry does. Only by providing specialised high quality products, can this broad range of requirements be satisfied.

Controlling a wide range of more or less aggressive fluids and gases can be a difficult task. This is why sealing materials have to be compatible with drilling and completion fluids, acid, corroslon Inhibitors and sour gas, etc.

Every selected seal has to meet high-pressure requirements of being able to hold zero to over 25.000 p.s.i. working pressure and the lifetime requirement of the seal is in terms of years.

Seals have to be resistant to a broad range of temperatures.Ideally, seals should be designed for temperatures between -40C and +200C, and can be easily extended for special applications.

Conforming to all seal standards is not only mandatory due to economic reasons, but also because seal failure can cause tremendous harm to the environment and human life.

As a supplier of high quality and reliable products to the industry, Marina Engineering Corporation understand these issues, enabling us to provide our wealth of feild experience and fundamental knowledge in sealing technology to support our customers' operations and to reduce NPT(Non Productive Time) and extend the life of your equipment.

Marina Engineering Corporation has the ability to provide industry standard sealing solutions to customers, in various materials, different sizes and quantities at a faster than ever pace.

The Marina Engineering Corporation team of engineers have the capability and experience to create custom-made products. Even the most complex problems can be solved by using the latest in house material technology and processes.

An Overview of the drililing of the activities oil and natural gas activities conducted wordwide

Typical Marina Engineering Corporation involvement in the Oil & Gas Industry

Drilling

BPO's choke & kill manifolds

Pipe handling systems

Control units

Mud systems

Downhole tools

Connections

Production

Wellheads

Control units

Completion tools

Gas treating facilities

Artificial lifting

Valves and Actuation

Transporation

Pipeline valves

Compressor stations

Pigging systems

Loading/unloading devices

Refineries

Valves

Flow lines

Compliant oil and gas sealing materials

Using the correct sealing material for a particular application is one of the key factors regarding safe and efficient operation. Controling a variety of fluids such as aromatic and naphthenic, hydrocarbon, corrosion inhibitors, acids, drilling and completion fluids, brines, carbon dioxide and hydrogen sulphide, are one of the many difficults faced in the oil and gas industry.

Only materials of the highest quality and standards have to be used, as a combination of these fluids have high pressures and high temperatures.

A variety of polymers are used in the oil and gas industry. Basically, they can be separated into four groups:

Elastomers

Thermoplastic elastomers

PTFE composite

Thermoplastics

For oilfield applications, elastomers are probably the frequently uesd materials. There are different types of elastomers available, though for most of the applications NBR(Nitrile Rubber) or HNBR(Hydrogenated Nitrile Rubber) are used. Higher chemical resistance can be provided by fluorinated elastomers (FKM/FPM, FFKM) where by the chemical resistance increases with increased Fluorine content.

When elastomers alone do not provide sufficient sealing capabilities for certain sealing applications. High quality materials such as PTFE or PEEK need to be used either in combination with elastomers for anti extrusion purposes or even as a sealing material itself.

Marina Engineering Corporation has developed high quality thermoplastic elastomers and is able to provide top oil field compatible polyurethane grades offer vastly superior abrasion and extrusion resistance combined with high compatibility of oil field fluids, including sour gas.

For some application, spring loaded seals are used in addition to oil field polymers.These spring materials also have to meet special requirements.

All the materials listed, are tested and developed in spareage's very own State-of-the-art R & D laboratory. The rubber materials and compounds are procured from well known global companies.